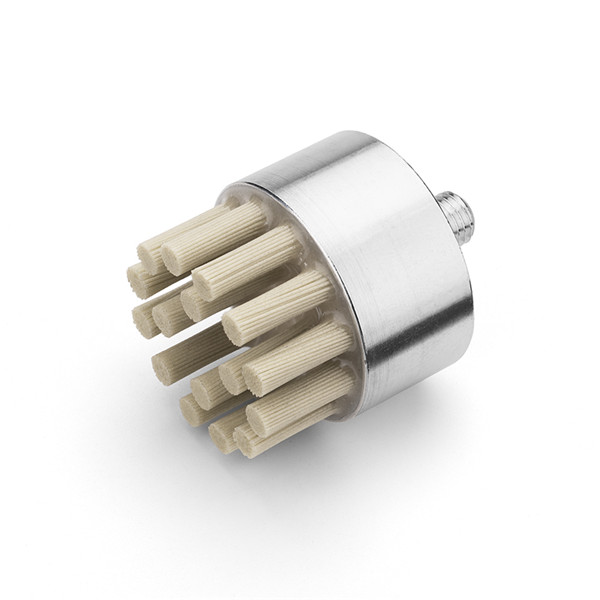

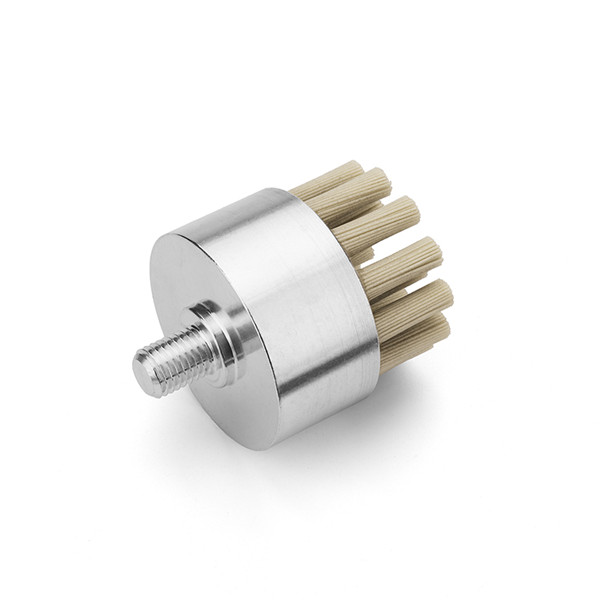

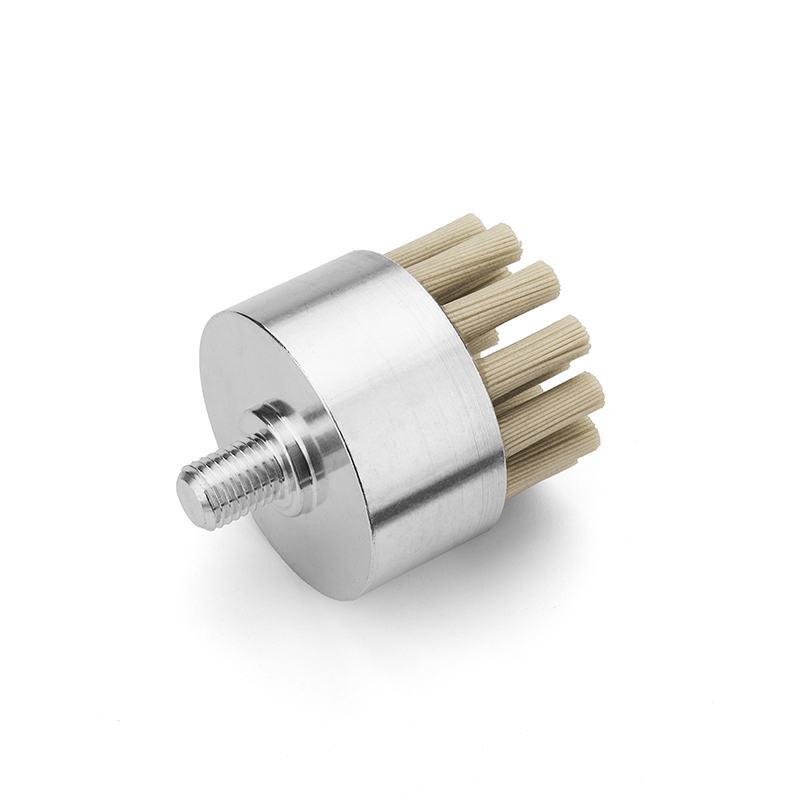

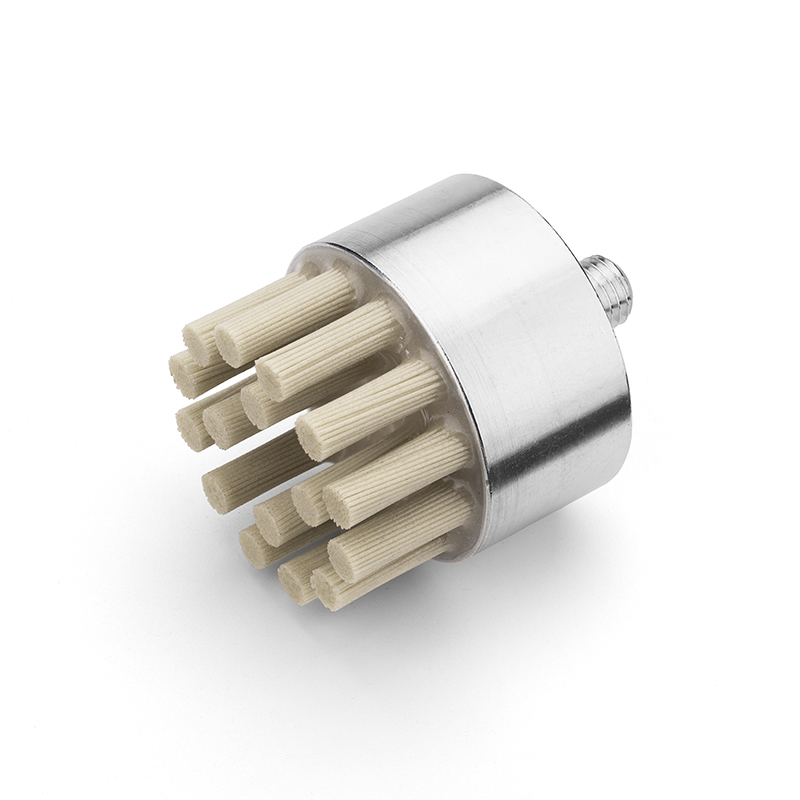

Chaw tsim tshuaj paus Fast tus me nyuam stainless hlau xov polishing kawg txhuam

Taw qhia:

Peb yog cov chaw tsim khoom ntawm Cov Txhuam Txhuam Txhuam Hniav uas tau siv dav rau kev tu lub hom phiaj hauv ntau lub tshuab ua haujlwm. Nws yog tsuas yog siv rau deburr thiab finely polish saum npoo ntawm cov khoom pov tseg, yog li hom thiab cov yam ntxwv ntawm cov txhuam hlau yuav tsum tau txiav txim siab raws li cov kev xav tau sib txawv.Txhua peb cov txhuam hniav yog tsim los siv cov khoom siv qib siab thiab cov cuab yeej tshiab los xyuas kom meej tias cov ua tau raws li cov qauv zoo thoob ntiaj teb & cov qauv.

Ntxiv rau qhov no, peb cov txhuam hniav muaj nyob rau hauv kev ua lag luam hauv ntau qhov ntau thiab tsawg, tsim thiab xim kom ua tiav cov kev xav tau ntawm cov neeg siv khoom.

Thaum machining lub Cheebtsam, ntau abrasive nylon yog sib npaug rau tib tus naj npawb ntawm saj zawg zog rasp uas yuav tsum tau khoov thiab ib txwm haum rau cov tivthaiv profile thiab nkag mus rau hauv zawj qhov uas lwm yam cuab yeej siv tsis tau, tshem tawm cov burrs, stains, xim thiab ntse npoo. thiab blunt mus rau ib tug du arc, thiab thaum kawg ua tiav qhov zoo tshaj plaws tshwm sim ntawm deburring, ntug buffing thiab nto tiav.

Cov nyhuv zoo tiav, ua haujlwm zoo, lub neej ua haujlwm ntev, kev ua haujlwm siab, kev nyab xeeb siab.Nws tuaj yeem siv nrog cov tshuab tsis siv neeg. Peb kuj muab customization raws li specifications nteg los ntawm cov neeg muas zaub.

Muaj nuj nqi:

Machining Center's - VMC / CNC / HMC

Tshwj xeeb Lub Hom Phiaj Tshuab

milling mark tshem tawm

Ntug Radiusing

Surface Enhancement nrog kev txhim kho hauv Ra tus nqi

Loj Flat Area Deburring

Kev tshem tawm xeb

END txhuam yog dav siv nyob rau hauv ntau yam workpiece polishing deburring.

CleaningFeature

Daim ntawv thov:

Kev lag luam hluav taws xob, kev lag luam hlau, xim hlau phaj, steel pobzeb, kho vajtse thiab cov khoom siv hauv tsev, metallurgy, hniav nyiaj hniav kub, tsheb thiab lwm yam kev lag luam, dav siv.

Txhuam txoj kab uas hla: Txheem 2 hli mus rau 30mm thiab ntau dua

Bristle qhov siab: Txheem 6mm, 8mm, 10mm, 15mm & 30mm thiab ntau dua

Raw khoom: Silicon carbide, Ntsuab Silicon, Ceramic, Aluminium Oxide, Pob zeb diamond

Grits: Txheem 60,80,120,180,240,320,500,600,800 & 1000 #

Hlau txoj kab uas hla: 0.2mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.1mm, 1.2mm, 1.5mm, thiab lwm yam.

Kev txiav txim siab:

1.Non-standard customized txhuam yog ua tau nrog tag nrho cov kab sib txawv, bristle heights, raw-khoom, grits & ua ke nrog xav bristle qhov siab.

2.Qhov kev xaiv ntawm bristles nyob ntawm lub substrate raug machined, tus nqi ntawm burrs thiab qhov kawg xov yuav tsum tau.

Qauv Parameters

| No | Cov khoom | Txoj kab uas hla (mm) | Txhuam txoj kab uas hla (mm) | Hlau qhov siab (mm) | Hlau txoj kab uas hla (mm) | Grit | Txhuam khoom | Max. siv (RMP) |

| 1 | S4D3T10t5 | 4 | 3 | 10 | 0.40 Nws | 240 # | Xiav ceramic | 6000 |

| 2 | s6d8t 9 | 6 | 8 | 9 | 0.60 ib | 320# | Aluminium oxide | 6000 |

| 3 | S6D15T2 | 6 | 15 | 2 | 0.40 Nws | 600 # | Pob zeb diamond | 6000 |

| 4 | S6D18.5T10 | 6 | 18.5 Nws | 8 | 0.75 ib | 240 # | Pob zeb diamond | 6000 |

| 5 | S6*30D23d4.5T10Z9 | 6 | 23 * 4.5 hli | 10 | 0.60 ib | 320# | Silicon carbide | 4500 |

| 6 | M8*10D35d4.5T15Z16 | 8 | 35 * 4.5 hli | 15 | 0.40 Nws | 600 # | Pob zeb diamond | 4500 |